Recently, we met two entrepreneurs who run a small business using 3D printing and 3D design. What makes these two entrepreneurs special is both their relationship and their ages: they’re siblings and they’re both still in primary school! Jessica and Elliott are in grade five and grade seven, respectively, at Craigburn Primary School. At school, Jessica enjoys English, while Elliott likes Science, Technology and Enterprise. Outside of school, they both enjoy normal kid pastimes like reading, drawing, cooking, gaming and writing but these two also spend 20+ hours a week working on their 3D printing business, G3D. Their dad, Stuart, and their mum, Anne-Marie, help out, too. We spoke with the G3D family to learn more about the kids’ business and how it all came about.

Elliot and Jessica, how did you first hear about 3D printing?

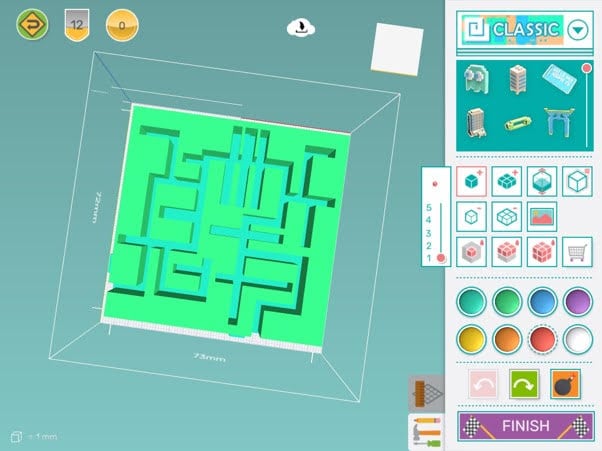

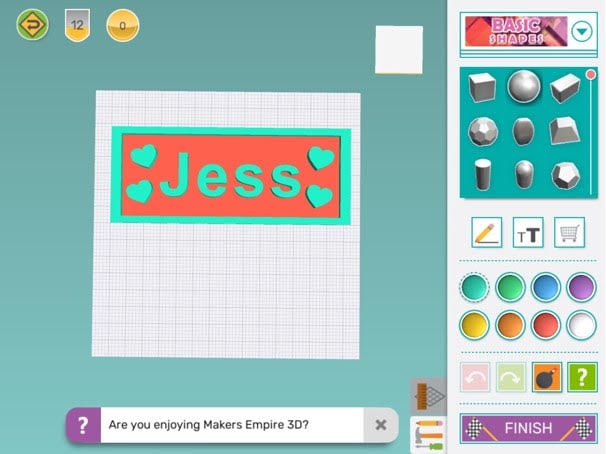

Elliott: I first learned about 3D printing at school because two of my school teachers went on a 3D design course with Makers Empire* and they won one UP Mini 2 printer and one UP Box printer. I started to use Makers Empire and I asked if I could print out one of my designs so my teacher showed me how to slice my design and use the 3D printer. After that, I knew that I wanted to get into it.

Jessica: I started to learn about 3D printing last year when Elliott started to do 3D design at home and I watched him do it. We also got our first 3D printer at home as a Christmas present and I started playing with Tinkercad and the printer to see what I could do.

How do you use 3D printing at school?

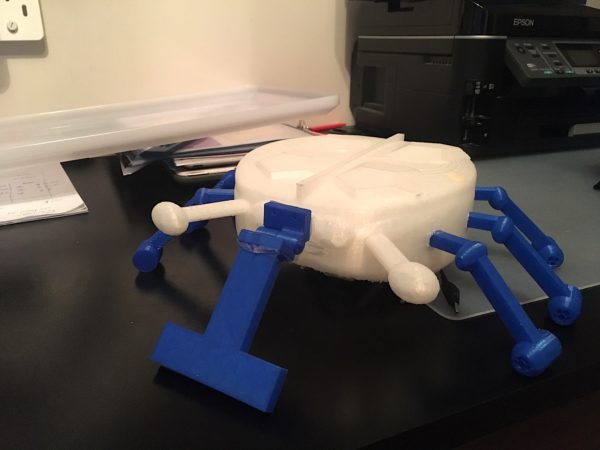

Elliott: We use 3D printing at school for school projects and prototypes for product ideas in Enterprise. I used the UP box at school to print a beetle for the tournament of minds last year.

Jessica: At school, I have not had a chance to use the 3D printers yet. But I use them a lot at home.

What do you like about 3D printing and design?

Elliott: I enjoy the challenge that it presents every day, learning new programs and sorting out technical problems that occur. It never gets boring as there is always a new challenge to face.

Jessica: I like 3D printing because I can customise things and it is really fun to play around with.

What 3D design programs do you use at home?

Elliott: I use Makers Empire, Tinkercad, and Autodesk Fusion 360.

Jessica: At home I use Tinkercad and I have found it easy to use it is good for designing keyrings and some custom designing.

What are the pros and cons of each?

Elliot: Makers Empire is a very easy program to use and get the hang of. Sometimes it can be a bit restrictive for larger projects.

Tinkercad is a very simple online CAD package and can be used for larger designs but there are not all of the tools that I would like it to have.

The pros and cons of Fusion 360 are that once you know how to use the program it is a very powerful design program to use but it is not intuitive to use and takes a long time to learn all of the features compared to Makers Empire and Tinkercad.

What do you use to print your 3D designs?

Elliott: We have two printers at home: one Flashforge inventor and one XYZ Da Vinci junior 1.0 pro.

How did you end up having your own company selling 3D printed designs?

Elliott: At school, me and my friends thought that it would be a good idea to run a skateboarding business but nobody was committed to starting it up so that failed. But then, once I knew how to 3D print I thought this would be a great idea for a business and that’s where it all started. We thought it would be a great idea to attend local markets to sell our products and show people the technology we use.

What kinds of designs do you like to make/sell?

Elliott: We make a lot of personalised bag tags and key rings, particularly for people with unusual names. We also make wall art, bookmarks and novelty pencil toppers. We can take custom orders for specific designs for people as well: we have just designed a replacement part for a customer for a set of blinds that have broken as she cannot get spares from where she bought them from.

What’s the coolest thing you’ve ever made?

Elliott: The coolest thing that we have made is a pen mould for a customer and a bug we designed for our school’s Tournament of Minds competition entry.

What do you enjoy about having your own business, G3D?

Elliott: Meeting our customers and learning how to use new programs and attending markets. Also the challenge of running a business. It’s great to earn our own money as well.

What have been some of the challenges?

Elliott: Some of the challenges at the start were learning how to use the design programs/slicing software, learning how business works and marketing to get customers. We were not having much success with marketing, so we decided to hire a digital marketing agency Bangkok to assist us. We have also had some problems with the machines such as nozzle blockages but we fixed this by stripping the nozzles and cleaning them with acetone. One of the challenges is the number of orders but we solve this by giving customers an order time and grouping the orders in colours so we can print a lot at the same time.

Who do you turn to for advice when you’re stuck?

Elliott: After my experience with the programs and the printers themselves I don’t usually run into problems. But if I do have a problem I ask my dad. If he can’t solve it then we contact Flashforge/XYZ printing. Our Mum helps us with the orders and answering customers.

I understand that you help your teachers at school with 3D printing?

Elliott: Yes, I do help my teachers at school with Makers Empire and the slicing software. If there is a technical issue I am the first person that they ask. I also helped the teachers at Aberfoyle Park Secondary School with their printers when I went to a STEM program there last term.

What advice would you give to kids who want to start their own business?

Elliott: Come up with something simple, original and unique to you don’t copy other people. Running a business is a challenge but once you learn how to use the programs/printers it is very rewarding. If you have problems try to solve them and don’t give up.

What are your future plans for your business?

Elliot: We are looking at getting a new printer and we are hoping it is going to be big. We are also wanting to go on a design course. I see G3D in the future as a cheap way of manufacturing individual items on a large scale.

Where can people view and buy your 3D prints?

Elliot: At local market stalls and online at Facebook.

Stuart, how has being an engineer influenced your kids?

Stuart: I think my kids, especially Elliott, have been influenced – they both ask me about my work and what it entails. I try and explain to them the importance of good engineering to produce things as poorly engineered products don’t work properly, break easily and, in the worst cases, are dangerous. I also try to show them examples of well-engineered and badly engineered products. Most of my experience has been in maintaining, designing and building military submarines and I try to show them how they work and how complex they are as products, I also explain to them why it is so important that the equipment on board works properly. I also try to show them that it can be very satisfying to produce a design that works to solve a real-world problem.

Tell us about your kids. I understand Elliott has always been a curious kid?

Stuart: Both my children are pretty bright (however, I might be biased!).

Jessica is very caring and passionate. She has been a dancer with a local school since she was 4. Her ambition at the moment is to be a doctor or a nurse as she really likes to help others. She has been interested in art and crafts from a young age and has become really interested in 3D printing as another way to produce designs.

Elliott has a classic engineer’s mind: he is always wanting to see how things work and take them apart. He has always been interested in computers and STEM and does coding at school. He was selected last year to attend a STEM program at Aberfoyle High school and whilst he was there he taught some of the teachers how to use their 3D printers properly!

How do you encourage their curiosity and support their learning?

Stuart: Taking time to show them how things work and encouraging open questions and answers are really good. I don’t just answer questions directly but give them direction to help them answer a question themselves. This gets them thinking on how to solve problems rather than them just being “spoon fed” solutions. We encourage them to do the research themselves and then present to us their findings. We provide constructive criticism but they need to find the answers themselves.

What toys would you recommend to parents to encourage making?

Stuart: Most kids now seem to have more interest in tablets than books, however, anything that lets children explore how things work would be an advantage. I think that actually building things really encourages that mindset so toys that let a kid’s imagination loose are really good. Some examples would be Lego, Meccano, and simple model kits – the simple electrical STEM kits are really good to show kids how things work and interact. For computer-based games, Minecraft is good to get them thinking about building things in a virtual world.

How much work does G3D involve?

Stuart: Their business has really taken off, much quicker than we envisaged so it takes a lot of time. Both of them get involved with designing prints and putting them onto the printers. They probably spend about 20 hours a week on the business to get orders out. As we have so many orders coming through, my wife and I need to give them quite a bit of support – most of the orders come from Facebook posts so my wife handles most of this as we don’t want the kids exposed heavily to social media at the moment. My role is primarily maintenance of the printers — they do suffer blockages and need to be stripped down occasionally — as well as helping Elliott with some of the more complex designs for special orders.

How can parents help their kids develop entrepreneurial behaviours?

Stuart: The key here is teaching kids the value of money, nothing is free and time and resources cost money. Getting them to do chores to earn pocket money is a great start. Once you get them to understand the link between work and pay then you can move it to the next stage, discuss with them what they are interested in and then open it out to how it could help others. Elliott and Jessica started another business, Bin Buddies, last year where they take peoples bins in & out and get paid to do it. One of the key areas is to look at simple solutions to problems and see if there is a gap in the market. Children have a good sense for this type of thing, you just need to discuss with them their ideas and then help them shape it. The other important message is to make children understand that it is ok to fail at something, as long as you learn from your failures. Most business undertakings suffer setbacks and failures before they become successful. People actually learn more from their failures than their successes.

We couldn’t agree more! Thanks to the G3D family for this interview. We’re thrilled that Makers Empire has helped inspire these young students and we look forward to following your business success.

*Craigburn Primary Schools is one of 170 schools that partnered with the Department for Education (SA) and Makers Empire for the pioneering 3D Printing in Schools project between 2016-2018. In 2019, another 100 South Australian Department for Education schools with a primary element will be able to participate in this project – expressions of interest are now open and will close at the beginning of April, 2019.

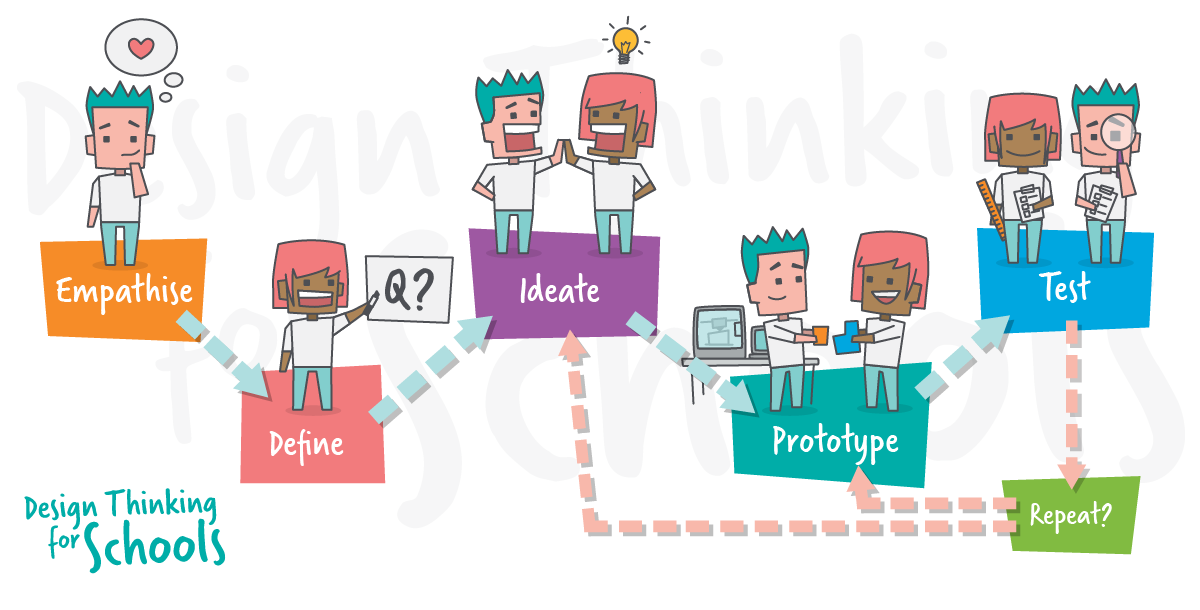

Feeling inspired? Makers Empire’s complete solutions for schools contain everything you need to teach Design Thinking, STEM and 21st-century learning skills with 3D design and 3D printing. Our pioneering 3D solutions for schools include 3D modelling software, over 150 lesson plans aligned with international standards and professional development. With Makers Empire, engaged students learn how to solve real-world problems and make their world better.